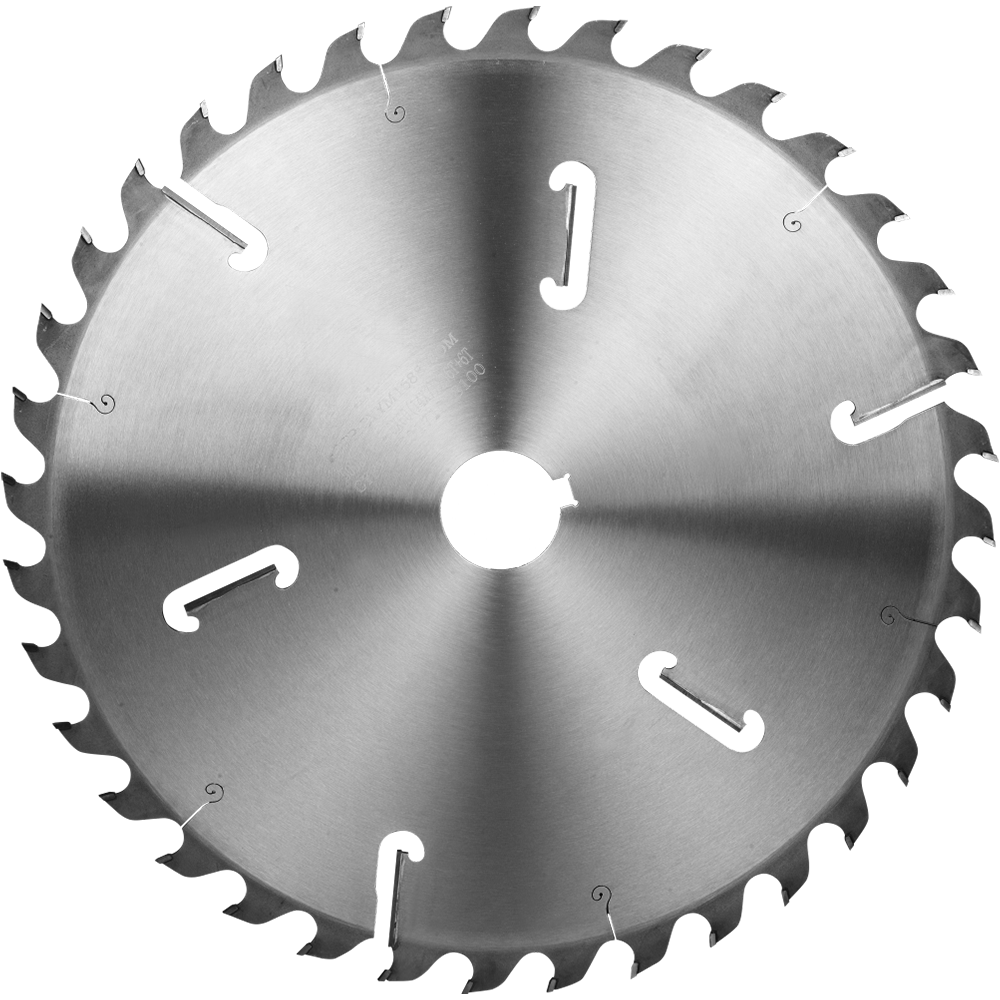

ZC Tools provides high-quality wholesale saw blades for professional and industrial use. Engineered for precision and durability, our blades ensure efficient cutting and long-lasting performance. Partner with us for reliable, bulk supply solutions.

At ZC-TOOLS, a premium brand, we focuses on the R&D, production and sales of high-end saw blades.It has a professional R&D team, skilled professionals, advanced processing machinery and equipment, and strict management system. The brand’s products are mainly used in the fields of furniture manufacturing, using imported German original substrates, high-precision welding of Luxembourg alloy, and optimized tooth design to maximize the cutting quality. The product has strong weld joints, stable performance,sharp edges and durability, and is suitable for all kinds of wood.

Our factory

Advanced processing machinery

Professional R&D team

Skilled professionals

| Feature | Description | Benefit |

| Material Composition | German original substrate alloy + Luxembourg precision welding | Superior strength & resistance to warping |

| Tooth Design | Acoustic-optimized tips (DIN 8037 compliant) | Reduced vibration & quieter operation |

| Blade Body | Hollow-ground chrome-vanadium steel with expansion slots | Stable, burr-free cutting |

| Surface Treatment | Thermo-chemical plating | Enhanced heat resistance & longer edge sharpness |

| Standards Compliance | DIN 40803, EN 847-1, TÜV Rheinland certified | Safety & international reliability |

| Available Sizes | Diameters 250mm – 1,820mm, teeth 40–130T | Compatible with table saws, miter saws, CNC circular saws |

1.Melamine Cutting

Smooth crosscuts in Melamin

2.Particleboard Cutting

Burr-free results in particleboard

3.MDF

Clean cuts without chipping

4.Solid wood composite board

handles Solid wood board

1. Proven Expertise: Backed by ZC-TOOLS Saw Blade Industry with 25+ years in premium saw blade R&D & manufacturing

3. Trusted Certifications and Acousic design: Certified to DIN 8037 acoustic design and DIN 40803 alloy standards

5. After-sales and technical support: Global technical service

2. High strength alloy: using imported German original substrates, high-precision welding of Luxembourg alloy

4. Eco-Friendly Manufacturing: energy-efficient production

1. Ensure the precision of the guide rails and spindle of the machine.

2. The inner and outer flanges must be the same size, and the flange surfaces should be clean and flat.

3. Wipe the saw blade clean before installation, especially ensuring there is no rust or adhering material at the contact point with the flange.

4. Before cutting, check that the saw blade is installed in the correct direction and is securely fastened.

5. Saw blades should be regrinded regularly and periodically to avoid uncontrolled use. When regrinding, ensure the saw blade is machined according to its original angle.

6. Before regrinding, thoroughly clean the base material and alloy cutting tip to remove rust and adhering material.

7. When regrinding, select a suitable diamond grinding wheel to ensure the cutting edge is sharp and prevent chipping. Grinding fluid should also be used.

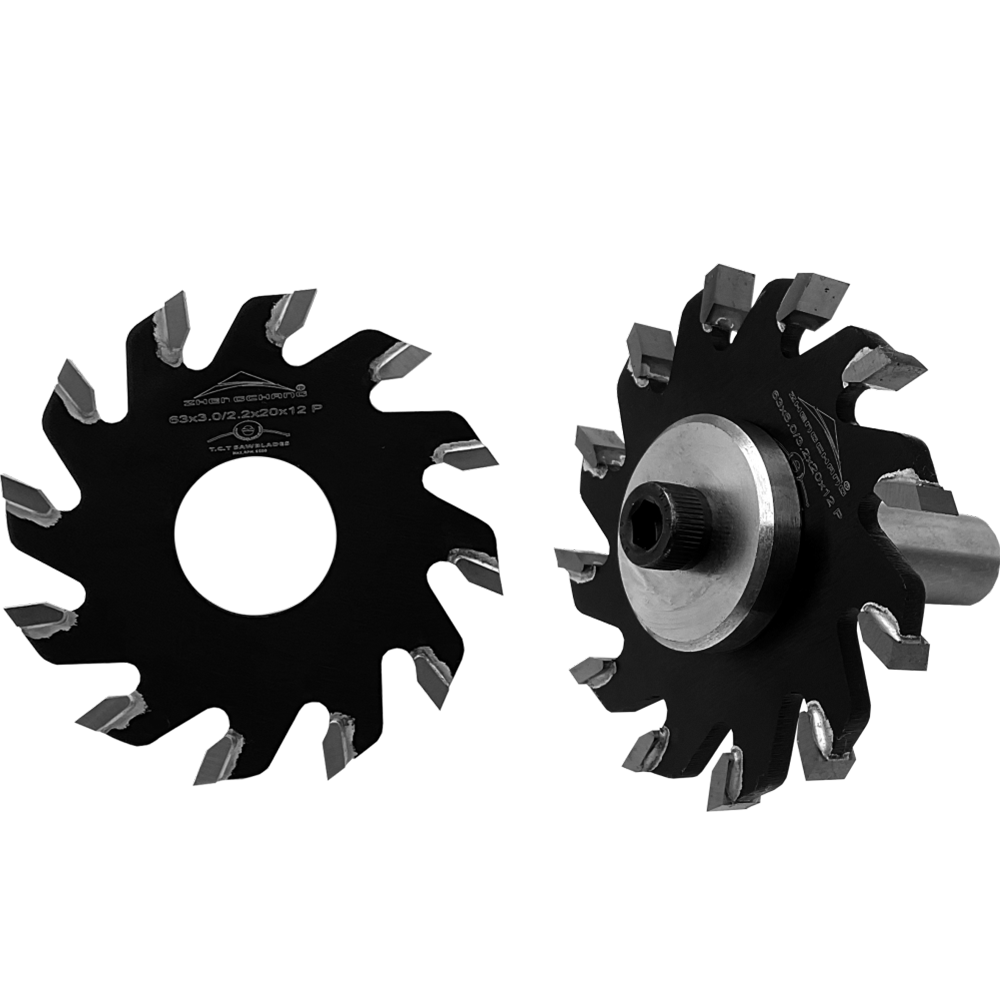

8. When enlarging the saw blade hole, it is recommended that the target diameter not exceed 20 mm of the original diameter. After enlarging, check the outer diameter runout to prevent severe saw blade eccentricity, which can affect cutting quality. Multi-blade saws are generally not recommended for enlarging holes.

9. For grinding, it is recommended to use automated equipment to minimize manual operation and prevent safety accidents.

1. Recommended feed rate for carbide saw blade sharpening: The feed ratio for the front and rear angles should be 1:3.

2. Proper sharpening is essential for ensuring the saw blade’s normal service life.

Incorrect sharpening: Sharpening only the front or rear angles will reduce the number of sharpening cycles, thus shortening the saw blade’s lifespan.

3. Sharpening must cover the entire wear area. Due to equipment precision limitations, we do not recommend manual sharpening of saw blades. Automatic sharpening equipment ensures the accuracy and consistency of sharpening both the front and rear angles.

4. Simultaneous sharpening of both the front and rear angles ensures the sharpness and stable service life of the carbide saw teeth. For safety reasons, it is not recommended to sharpen carbide saw teeth with a thickness of less than 1 mm.

Although re-grinding reduces the length of the saw teeth, the design of the chip grooves on the saw blade ensures that the re-grinded saw blade has sufficient space for chip removal, thus avoiding poor chip removal due to re-grinding of the saw teeth. Therefore, it is not necessary to re-grind the grooves during re-grinding.

If the saw teeth fall off or break, they should be replaced by a designated grinding center. Welding should be done using a high-frequency welding machine, supplemented with appropriate solder and flux.