Even the most advanced woodworking CNC router can only perform as accurately as its cutting tools allow. In modern woodworking, the cutter is not just a consumable part — it’s the core determinant of surface finish, precision tolerance, and production efficiency.

Yet, many workshops — even professional ones — still suffer from poor cutting results due to improper tool use or maintenance. The consequences are costly: rough edges, increased tool breakage, excessive downtime, and inconsistent dimensions across batches.

In this article, we’ll explore the five most common mistakes when using woodworking cutters, and how professional engineering solutions — such as those developed by ZC TOOLS — can help you avoid them.

1. Using the Wrong Cutter for the Material

Every wood-based material reacts differently to cutting stress, chip load, and heat dissipation. Selecting the wrong cutter geometry or carbide grade directly impacts the surface quality and tool life.

- Softwood (e.g., Pine, Cedar): Requires ultra-sharp edges and higher feed rates (6–10 m/min) due to its low density.

- Hardwood (e.g., Oak, Beech): Demands cutters with higher wear resistance and lower feed rates (3–6 m/min) to prevent burning.

- MDF / Plywood / Laminated Boards: Need spiral or compression bits that improve chip evacuation and prevent edge chipping.

👉 Common mistake: Using a metal-cutting tool or a generic router bit for wood.

Such tools have incorrect rake angles and edge geometries, leading to excessive friction, chipping, and thermal degradation of the wood surface.

💡 ZC TOOLS’ Solution:

ZC TOOLS Tungsten Carbide Spiral Cutters are engineered with optimized rake and clearance angles for wood composites, ensuring clean chip evacuation and extended lifespan. The use of micro-grain carbide (≤0.8 μm) enhances edge strength, making them ideal for continuous CNC routing applications.

2. Ignoring Tool Wear and Replacement Intervals

Tool wear is inevitable — but uncontrolled wear is preventable. Continuing to use dull cutters can cause up to 30% loss in feed speed efficiency and drastically reduce cutting precision.

Typical signs of tool wear include:

- Burn marks or dark edges on the wood surface

- Increased cutting vibration or “screaming” noise

- Dimensional inaccuracies across multiple passes

- Chipped or rounded cutting edges visible under magnification

Once the cutting edge wear exceeds 0.2 mm, the tool should be reground or replaced. Delaying replacement leads to thermal stress on the spindle and higher energy consumption.

💡 ZC TOOLS’ Solution:

The brand promotes predictive maintenance instead of reactive replacement. By tracking each cutter’s runtime and material throughput, workshops can anticipate wear before it affects product quality.

ZC TOOLS also offers regrinding services for their carbide tools, restoring up to 90% of original cutting performance — a cost-effective and sustainable maintenance practice.

3. Incorrect Feed Rate and Spindle Speed

The relationship between feed rate (F), spindle speed (N), and chip load (fz) defines how efficiently a cutter removes material. Miscalculating these values is one of the most common causes of tool failure and poor finish quality.

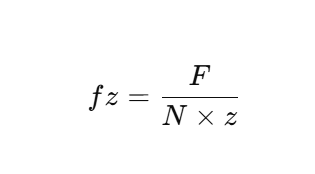

Key formula:

where z = number of flutes.

Common scenarios:

- Feed rate too high → causes tool breakage, vibration, and edge tearing.

- Feed rate too low → leads to excessive heat buildup, resin accumulation, and burning.

Example Reference for Wood Materials:

| Material | Spindle Speed (RPM) | Feed Rate (mm/min) | Chip Load (mm/tooth) |

|---|---|---|---|

| Softwood | 18,000–22,000 | 5,000–9,000 | 0.25–0.35 |

| Hardwood | 16,000–20,000 | 3,000–6,000 | 0.15–0.25 |

| MDF | 18,000–22,000 | 4,000–7,000 | 0.20–0.30 |

💡 ZC TOOLS’ Solution:

Every ZC TOOLS cutter is provided with a detailed technical datasheet, including optimal RPM and feed recommendations.

This ensures operators can precisely match cutting parameters to material type and tool geometry — whether they’re using drill bits or saw blades.

Proper calibration not only enhances tool life but also reduces the risk of spindle overload and inconsistent cutting depth.

4. Poor Chip Evacuation and Dust Control

Efficient chip evacuation is critical in CNC routing. When chips remain trapped in the cutting path, they act as abrasives, increasing tool wear and heat accumulation. MDF and particleboard are especially prone to this issue due to their resin content.

Effects of poor chip evacuation:

- Overheating at the cutting edge

- Burn marks on laminated surfaces

- Reduced cutting accuracy due to re-cutting chips

- Shortened tool lifespan

Best Practices for Chip Management:

- Use up-cut bits for single-sided boards.

- Use compression bits for laminated panels to prevent tear-out.

- Ensure a high-efficiency dust extraction system (≥ 20 m/s airflow).

- Avoid excessive step-down depth — limit to 2–3× cutter diameter per pass.

💡 ZC TOOLS’ Solution:

The company’s Diamond-Coated Router Bits feature a non-stick surface that minimizes resin adhesion, ensuring smooth chip flow.

The optimized flute design enhances chip evacuation at high feed speeds, preventing clogging and reducing temperature rise by up to 15°C during continuous cutting.

5. Improper Tool Holding and Installation

Even the best cutter will perform poorly if it’s installed incorrectly. Improper tool holding introduces runout, vibration, and premature edge failure.

Typical installation errors:

- Using worn or dirty collets

- Insufficient tightening torque

- Inconsistent tool projection (too long)

- Failure to align tool shank properly

Runout as small as 0.02 mm can cause visible cutting marks and reduce surface smoothness. At 20,000 RPM, such imbalance can severely damage the spindle bearings.

💡 ZC TOOLS’ Solution:

All ZC TOOLS cutters are manufactured with high concentricity tolerance (≤0.01 mm) to ensure stable rotation at high speed.

Users are advised to:

- Clean collets with isopropyl alcohol before each tool change

- Use a calibrated torque wrench for tightening

- Replace collets after 500 operating hours

This attention to installation precision greatly extends both cutter and spindle lifespan.

✅ Conclusion

Avoiding these five common mistakes can dramatically improve your CNC woodworking performance — achieving smoother finishes, faster production cycles, and lower overall tooling costs.

When operators understand the interplay between tool geometry, feed dynamics, and material behavior, every cut becomes predictable, repeatable, and efficient.

ZC TOOLS continues to develop precision-engineered woodworking cutters, focusing on:

- Long-term durability under high-speed operation

- Edge stability across composite and hardwood applications

- Cost efficiency through optimized carbide and coating technologies

By investing in proper cutter selection, maintenance, and setup, manufacturers can turn every CNC operation into a controlled, high-precision process — transforming tool usage from a cost factor into a profit driver.

📎 Summary Table

| Mistake | Effect | Engineering Solution |

|---|---|---|

| Wrong cutter type | Chipping, overheating | Match geometry & material |

| Dull cutters | Rough finish, low efficiency | Predictive tool replacement |

| Wrong speed/feed | Burn marks, vibration | Adjust parameters via datasheet |

| Poor chip evacuation | Overheating, clogging | Improve airflow & coating |

| Loose tool holding | Runout, tool breakage | Maintain collet precision |