High-performance Two-Flute Combination-Cut End Mill designed for smooth cutting, reduced tear-out, and precision machining of particleboard, MDF, plywood, multilayer panels, and hardwood. Ideal for CNC woodworking, furniture production, and door panel processing.

The Two-Flute Combination-Cut End Mill is engineered for high-efficiency, high-precision machining of wood and wood-based panel materials. Featuring a dual-edge composite cutting geometry, it delivers exceptionally smooth cutting performance, reduced tear-out, and stable operation during CNC routing.

Ideal for furniture production, wooden door machining, panel fabrication, and other professional woodworking applications.

The optimized Combination-Cut geometry enhances chip evacuation, minimizes chipping, and ensures clean edge finishes on wood-based materials.

The balanced flute structure provides excellent cutting smoothness and maintains accuracy during drilling, trimming, and shaping tasks.

Manufactured from high-quality solid carbide for long tool life, improved wear resistance, and reliable performance under continuous industrial use.

Suitable for particleboard, MDF, plywood, multilayer boards, hardwood, and decorative panels.

Fully compatible with CNC woodworking routers, processing centers, and automatic door-making machines.

Wooden door drilling & trimming

Particleboard and MDF cutting

Plywood and multilayer board machining

Hardwood shaping and trimming

Furniture panel processing

Cabinet and interior decoration production

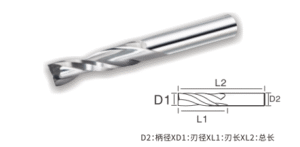

| Size (mm) | D2 (Shank) | D1 (Cutting Dia.) | L1 (Flute Length) | L2 (Overall Length) |

|---|---|---|---|---|

| 4×4×25×50 | 4 | 4 | 25 | 50 |

| 6×6×32×60 | 6 | 6 | 32 | 60 |

| 8×8×32×60 | 8 | 8 | 32 | 60 |

| 8×8×42×80 | 8 | 8 | 42 | 80 |

| Custom sizes | — | — | — | — |

Customized specifications are available upon request.

Clean, smooth cutting with significantly reduced tear-out

Long-lasting carbide construction with strong wear resistance

High stability for industrial CNC woodworking

Compatible with a wide range of wood-based materials

Optimized for door manufacturing, furniture production, and panel processing

Professional-grade tooling designed specifically for woodworking industries

Strict quality control ensures dimensional accuracy and consistency

Advanced composite flute geometry for superior surface finishing

Customizable options to match your CNC and processing requirements

Trusted by manufacturers of doors, cabinets, furniture, and decoration panels

Q1: What materials can this end mill cut?

A1: It is ideal for wooden doors, particleboard, MDF, multilayer panels, plywood, decorative boards, and hardwood.

Q2: Can this tool be customized?

A2: Yes, custom diameters, flute lengths, and overall lengths can be manufactured based on your processing requirements.

Q3: Is it suitable for high-speed CNC routers?

A3: Absolutely. Its solid carbide construction and balanced geometry allow stable performance at high spindle speeds.

Q4: Does it help reduce chipping?

A4: Yes. The Combination-Cut flute design effectively minimizes tear-out, especially on laminated or veneered boards.

The ZC-TOOLS Two-Flute Combination-Cut End Mill is a reliable, high-performance cutting tool designed for woodworking professionals. With its advanced composite cutting geometry, durable carbide build, and excellent material compatibility, it ensures clean edges, reduced chipping, and efficient processing across a wide range of applications.

Whether you’re producing wooden doors, furniture panels, or complex wood components, this tool delivers the precision and stability you need for superior CNC machining results.