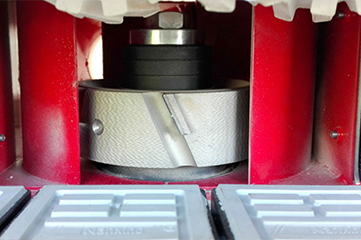

ZC Tools Diamond Pre-Milling Cutter for Woodworking and Composite Panels – Ultra-Precise & Long-Lasting Performance

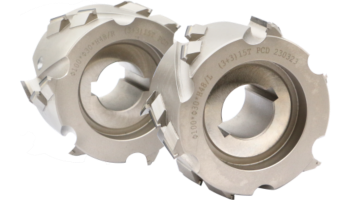

At ZC-TOOLS, brings over 20 years of expertise in crafting the Diamond Pre-Milling Cutter, a premium tool specifically designed for use on edge banding machines. Our dedicated R&D team, skilled engineers, and state-of-the-art manufacturing facility ensure top-tier quality. Utilizing polycrystalline diamond (PCD) inserts and advanced steel bodies, these cutters excel in precision edge trimming, and woodworking. Ideal for furniture manufacturing for high-precision applications on edge banders, our cutters feature optimized cutting geometries and robust weld joints, delivering sharp edges and long-lasting performance.

Our factory

Advanced processing machinery

Professional R&D team

Skilled professionals

| Feature | Description | Benefit |

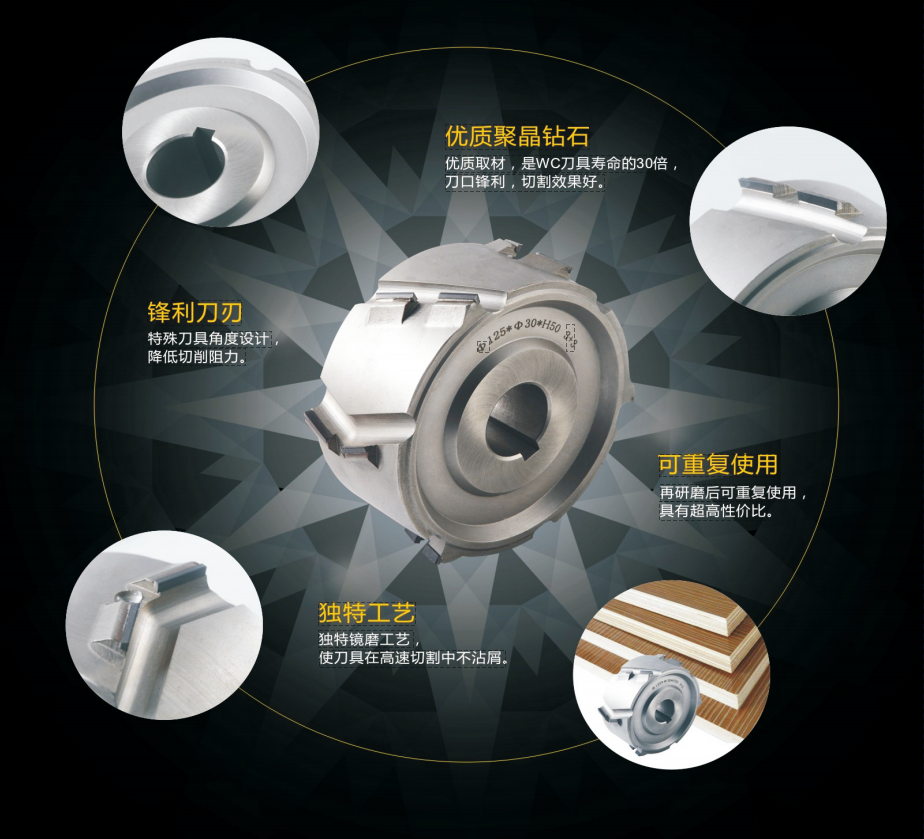

| Material Composition | Made with premium polycrystalline diamond material, offering 30 times the lifespan of WC cutting tools. | Provides exceptional durability, sharp edges, and superior cutting efficiency. |

Sharp Blade Design | Features a special tool angle design to reduce cutting resistance. | Enhances cutting precision and reduces wear on the tool. |

Reusable | Can be reused after regrinding with ultra-high cost-effectiveness. | Offers significant cost savings and sustainability. |

Unique Craftsmanship | Unique mirror grinding process ensures the tool does not stick to chips during high-speed cutting. | Improves performance and reliability in high-speed operations. |

Precision Machining | Manufactured using a five-axis machining center with high controllable accuracy. | Ensures consistent, high-precision results in every cut. |

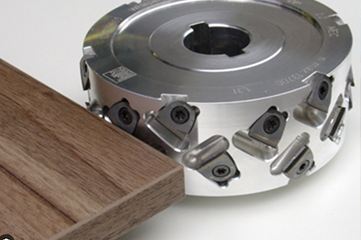

1.Edge Trimming on Edge Banders

Precise pre-milling and finishing of edges on wood panels

2.Copy Milling and Finishing

Clean edge profiles on veneered particleboard (MDF) and laminates.

3.High-Volume Production

Efficient edge processing for furniture panels and decorative trim.

4. Specialized Materials

Handles abrasive materials like FRP/CFRP with minimal wear on edge banders.

1. Proven Expertise: Backed by ZC-TOOLS Saw Blade Industry with 25+ years in premium saw blade R&D & manufacturing

3. Trusted Certifications: ISO 9001 and Taiwan Excellence Award (2022).

5. After-Sales Support: Global technical assistance

2. Premium Materials: Uses PCD technology and high-grade steel.

4. Innovative Design: Engineered for precision edge banding performance.

Multi-layer board (plywood), MDF (medium-density fiberboard), particleboard, solid wood board

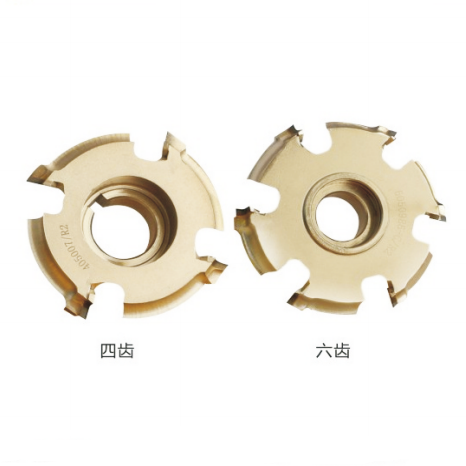

More teeth result in better performance, higher cut smoothness, and longer lifespan. However, one should not blindly choose a cutter with a high number of teeth. Generally, 9 or 12 teeth are sufficient for most applications. The cutting edges are angled and segmented; this angled arrangement during high-speed rotation ensures a smoother cut and reduces the risk of edge chipping.

When replacing your cutting tool, it’s recommended to choose one with a diamond cutting edge. Diamond is more wear-resistant than alloy cutting tools, and its lifespan can be 4 to 5 times longer. Furthermore, diamond-cut pre-milling cutters use laser-ground cutting edges for higher precision, better sharpness, and greater durability.

A double keyway tool can be installed on a single keyway tool, but if the single keyway tool originally had two keyways, it will definitely not fit and will get stuck. You can choose the appropriate size based on the existing tools on the edge banding machine; this should generally prevent errors.