For those who love DIY or are skilled woodworkers, the circular saw is essential. Keeping it well-maintained is key to its success. Learning to switch blades is crucial for care and safety. This guide shows how to do it, protecting your work and peace of mind.

Key Takeaways

- Understanding the significance of circular saw maintenance for DIY projects and professional tasks.

- Steps to safely power off your circular saw before the blade replacement.

- Engagement of the spindle lock: A crucial step in the blade replacement process.

- How to remove the arbor nut and old blade, emphasizing precision and safety knowledge.

- Tips for cleaning and inspecting the saw before installing a new blade.

Introduction to Circular Saw Maintenance

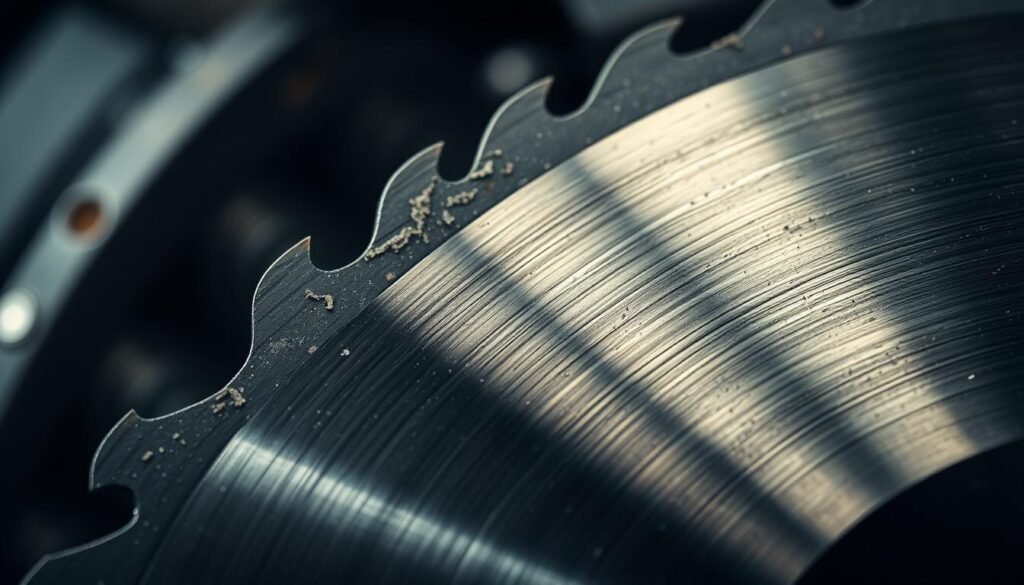

Keeping your circular saw in good shape is key to its performance and life span. A well-cared-for saw means better cuts and more safety for the user. We’ll talk about how to take good care of power tools, especially circular saws, focusing on keeping the saw blade in top shape.

For your circular saw to work well, follow a regular maintenance plan. This includes cleaning, checking over the saw, and storing it right. Here are some tips to keep your saw running smoothly:

- Regularly clean the saw blade to remove any debris and resin that could impede performance.

- Check the blade for signs of wear or damage and replace it when necessary to avoid poor cut quality and increased effort during cutting.

- Ensure that all safety features of the saw are functional and intact.

But taking care of your tool is more than just cleaning and handling. Keeping the saw blade sharp is crucial. A sharp blade makes for easy cuts, puts less stress on the motor, and wears down the saw less.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean the blade | After every use | Prevents build-up, maintains cutting efficiency |

| Inspect blade sharpness | Monthly | Ensures smooth cuts, reduces strain on the motor |

| Check mechanical parts | Bi-annually | Guarantees safety, prolongs saw lifespan |

Regular care of your circular saw boosts its performance and safety. By keeping up with blade maintenance and tool care, your saw will be ready for many projects.

What Makes Cordless Circular Saws Unique

The invention of cordless circular saws changed how we use portable tools. They offer freedom and flexibility for cutting tasks. Thanks to lithium-ion batteries, there’s no need for cords. This lets users move freely and reach tight spots easily.

Cordless saws are super portable. They work in places without plugs, perfect for outside or far-off jobs. Lithium-ion batteries make them powerful and long-lasting. These batteries get better and last longer over time.

| Battery Voltage | Typical Use Case | Pros | Cons |

|---|---|---|---|

| 18V | Light-duty tasks | Lightweight, easy handling | Less power for tough cuts |

| 36V | General building tasks | More power, longer use | Heavier than 18V models |

| 60V | Heavy-duty construction | Maximum power and runtime | Weight can impact maneuverability |

Cordless saws are now a key tool for many. They are perfect for both hobbyists and professionals. You can choose the right voltage for your project. Whether it’s light trim work or big construction jobs.

Lithium-ion batteries have made cordless circular saws better and powerful. This progress means more options for woodworkers and builders. As the batteries get better, these tools will become even more essential.

Essential Tools and Safety Gear for Blade Replacement

Changing a blade on your circular saw needs the right safety equipment. This makes sure the process is safe and efficient. You must have strong cut-resistant gloves to protect your hands from cuts.

To replace the blade smoothly, you need the correct blade change tools. Tools like a hex wrench are important for this task. Make sure you have good lighting and a clean brush for your equipment.

| Safety Equipment | Required Tools for Blade Change |

|---|---|

| Cut-resistant gloves | Hex wrench |

| Protective goggles | Cleaning brush |

| Ear protection | Spare blade-specific for saw model |

Make sure your workspace is well-lit and organized. This helps keep you safe and focused. Check that all your tools and safety gear are close by before you start. This ensures a smooth and safe blade change.

How Do You Change a Blade on a Circular Saw

Changing a circular saw blade is key for woodworking. It ensures your tool works well. Follow this guide to switch blades safely and easily.

Unplugging and Preparing Your Saw

First, turn off the circular saw completely. Take out any batteries to stop accidental starts. This step keeps you safe from unexpected harm.

Engaging the Spindle Lock and Removing the Old Blade

Next, use the spindle lock to keep the blade from moving. You’ll find this lock on the saw’s front. Now you can safely remove the blade. Loosen and take off the blade bolt or washer, then pull the blade off.

Cleaning and Preparing for the New Blade

After removing the old blade, clean away any debris or dust. Cleaning helps your saw last longer. It also makes sure the new blade works well.

Installing the New Blade and Ensuring Secure Attachment

Putting in the new blade is easy after cleaning. Put the new blade on the spindle the right way. Reattach and tighten the bolt or washer while holding the spindle lock. Make sure the blade is really secure to avoid wobble or problems while using it.

Now your saw has a new blade and is ready for sharp, accurate cuts. Always check your setup is correct before starting a new project.

Understanding Circular Saw Blade Types

Picking the right circular saw blade is key for great results in cutting projects. If you’re cutting wood, metal, or other stuff, knowing blade types helps a lot. This knowledge improves your work’s quality and efficiency.

Wood cutting blades are made for all kinds of wood, like hardwoods and engineered woods. These blades have different teeth setups. Some are for fine cuts, and others for big tasks like framing.

Blades for Wood Cutting

For wood cutting blades, you have many choices. There are blades with big teeth for fast cuts and blades with small teeth for precise work. Carbide-tipped blades last longer and are very durable.

Specialty Blades for Other Materials

There are specialty saw blades for cutting metal, plastic, and composite too. They vary by tooth design and materials. Some have carbide or diamond tips for tough materials.

Knowing the differences helps you pick the right blade, making your saw work better and safer. Always match your saw’s specs with the right blade. Look for a ‘7’ on some blades to find the best one for your job.

Recognizing When to Replace Your Circular Saw Blade

It’s vital to change your circular saw blade on time. This ensures great cutting performance and tool safety. Knowing when the blade is worn is key. It helps keep the tool working well and safely. Let’s look at how to know when to change the blade. We’ll see how it affects performance and safety.

Looking closely at the blade shows wear signs. Missing or broken teeth mean it’s time to change. If a blade is really rusty or corroded, replace it. Also, if carbide tips are damaged or not sharp, the blade won’t cut well.

When a blade is dull, cutting is harder and not clean. This can be dangerous. A dull blade might make the saw kick back or get stuck. This could cause an accident. Too much vibration, loud noises, or burn marks on wood also show the blade is dull. Both your work quality and safety are at risk.

For tips on checking your saw blade, this site is helpful: how to tell if your saw blade needs to be sharpened or.

Another important thing is how many times a blade has been sharpened. If a blade has been sharpened a lot but still doesn’t cut well, it might need replacing. This ensures your tool stays safe and cuts well.

Knowing when to change the blade keeps your circular saw working great. It also makes sure it’s safe to use. Regular checks and taking care of your tool can make it last longer. It can also improve your work.

Step-by-Step Guide to Removing the Old Blade

When circular saw blade removal is done right, it keeps you safe. It also looks after your power tool. Make sure to follow this guide closely for safe and effective removal. Remember, always keep power tool safety in mind.

- Disconnect the Power Source: First, make sure your circular saw is off and unplugged. This stops the saw from turning on by accident while you work.

- Clean the Blade Area: Get rid of any dust or debris. A clean area makes it easier to see and work.

- Engage the Spindle Lock: Find and press the spindle lock button. This stops the blade from moving so you can safely remove the nut.

- Loosen and Remove the Arbor Nut: Use the wrench that came with your saw to loosen the nut. Follow your saw’s manual because some nuts turn the opposite way. This is key to removing the blade safely.

- Remove the Blade: After loosening the nut, gently take the blade off the saw. Be very careful to avoid hurting yourself or damaging the blade or saw.

You’ve now finished the blade changing steps. You can either clean the blade area well or put on a new blade. Always check your saw’s manual for specific instructions. This makes sure you follow power tool safety rules.

Installing the New Blade for Optimal Performance

Setting up your circular saw blade right is key to better cuts. You need to be careful with every part and step. This makes sure your circular saw works its best. Follow these steps to make the blade work well.

Start by putting the new blade on so the teeth face forward. This is important because it decides how well the saw cuts. The blade must be tight against the inner washer. It should only spin as needed.

| Component | Detail | Function |

|---|---|---|

| Outer Washer | Position correctly | Secures the blade |

| Arbor Nut | Apply recommended torque | Ensures strong fixation without overtightening |

Then, put the outer washer in its spot. It’s really important for keeping the blade stable while in use. Carefully put the arbor nut on the shaft. Be sure not to mess up the threading. Tighten the nut to the suggested level. Don’t make it too tight to prevent blade damage.

- Verify blade alignment: Make sure the blade is straight and lines up with your cut.

- Check mounting security: Gently shake the blade to see if it’s firm and safe.

- Perform a test cut: Always cut a scrap piece first to see if everything’s set right.

Putting your circular saw blade in correctly boosts cutting power. It also makes your blade and saw last longer. Paying close attention when setting it up really helps your cutting work.

Testing and Adjusting After Blade Replacement

After replacing your circular saw blade, there are important steps to follow. These include making test cuts, checking blade alignment, and saw calibration. These steps make sure the saw cuts well and is safe to use.

First, make sure the battery is back in place or the power is connected. Then, find a piece of scrap wood to use. A test cut helps you see how the saw is working. Look for any shaking, sticking, or weird noises that might mean the saw needs more tuning.

| Test Description | Expected Outcome | Action Required |

|---|---|---|

| Initial Test Cut | Smooth, clean cut through wood | Confirm setup is correct; no action needed if successful |

| Blade Alignment Check | Blade is perpendicular to baseplate | Adjust blade if misaligned |

| Saw Calibration | Saw runs smoothly with no deflection | Calibrate saw to correct any issues |

It’s important for the blade to be just right with the baseplate for clean cuts. If you need to make changes, look at your saw’s manual on how to do a saw calibration. After you do these steps, your circular saw will be ready for bigger tasks. You’ll be able to cut precisely and safely.

Conclusion

Maintaining your circular saw makes it work better and last longer. It’s important for anyone who loves DIY projects. Taking care of the blade is key. You must inspect and change it regularly. This makes cutting safer and smoother.

This guide taught us when to change the blade and what kind to use for each job. Knowing how to replace the blade correctly is also important. These steps make your saw last longer and turn tough tasks into easy ones. For DIY lovers, being efficient is very important.

So, proper care and keeping your blade in good shape are essential. They help you do better work and feel proud of what you create. Always remember, a well-kept tool is the best partner for a craftsperson.

FAQ

What safety precautions should I take before changing a circular saw blade?

First, make sure the saw is off and the battery is out. This stops it from accidentally starting. Wear gloves that resist cuts. Also, make sure your work area is clean and well-lit.

How can I tell if my circular saw blade is dull and needs replacing?

Look for burn marks on the wood and if cutting takes more effort. Also, rough cuts, damaged teeth, and strange noise mean it’s time for a new blade.

What are the steps to safely remove an old circular saw blade?

First, disconnect the power and take out the battery. Clean the blade area. Then, engage the lock and loosen the nut to remove the blade. Watch out for reverse threads and handle the blade with care.

How do I install a new blade on my circular saw correctly?

Start by cleaning the new blade. Make sure the teeth are facing the right way when you mount it. Put everything back in place and tighten the nut as the maker suggests.

What kinds of blades should I use for different woodworking projects?

For rough cuts like framing, use blades with fewer, larger teeth. Use blades with lots of small teeth for detailed work. Carbide-tipped blades are good for many projects because they last longer and are safer.

How do I test the new circular saw blade after installation?

Put the battery back in and make a test cut on some scrap wood. Hold the saw steady and watch how it cuts. If it vibrates or makes odd noises, adjust it to work right.

What should I look for in a cordless circular saw when shopping for one?

Think about the voltage. It changes how powerful and heavy the saw is. Look for a saw that’s easy to handle, feels good in your hands, and has enough battery life for your work.

Can blade wear really affect the performance and safety of my circular saw?

Yes, it can. Worn blades make cuts worse and can cause dangerous accidents. Always keep your saw in good shape and change the blade when needed for safety and good results.

Are there any special considerations when handling high-voltage cordless circular saws?

High-voltage saws cut better but are heavier. This extra weight can make them harder to use for a long time. Choose a saw that has the right balance of power and comfort for you.