High-performance Three-Flute Rough Milling Cutter for woodworking and CNC machining. Durable tungsten steel, sharp cutting edges, smooth burr-free finish, ideal for wood, particleboard, and hardwood.

The Three-Flute Rough Milling Cutter is a high-performance CNC woodworking tool designed for furniture factories, woodworking machinery, and industrial CNC machining centers. Built with imported tungsten steel and optimized cutting geometry, it delivers smooth, burr-free surfaces, extended tool life, and higher production efficiency.

This cutter is ideal for wood, multilayer board, particleboard, and hardwood, making it the preferred choice for woodworking industry customers worldwide.

Sharp Cutting Edge & High Wear Resistance – Ensures consistent precision and long-lasting durability.

Professional CNC Wood Milling Design – Reduces tear-out, improves chip removal, and achieves smooth finishes.

Extended Service Life – Manufactured with imported tungsten steel base material for superior strength.

Large Spiral Chip Slot – Enhances chip evacuation, prevents clogging, and reduces heat buildup.

Universal Compatibility – Suitable for CNC routers, woodworking machinery, and production lines.

Wood Door Drilling – Precise holes without chipping or tear-out.

Multilayer & Particleboard Milling – High material removal efficiency with minimal damage.

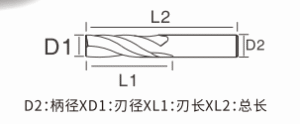

| Size (mm) |

D2 |

D1 |

L1 |

L1 |

Suitable |

|---|---|---|---|---|---|

| 8×55×100 | 8 | 8 | 55 | 100 | processing wooden door drilling, particleboard, multilayer board, hardwood |

| 10x55x100 | 10 | 10 | 55 | 100 | processing wooden door drilling, particleboard, multilayer board, hardwood |

| 12x55x100 | 12 | 12 | 55 | 100 | processing wooden door drilling, particleboard, multilayer board, hardwood |

| 12.7x12x80x120 | 12.7 | 12 | 80 | 120 | processing wooden door drilling, particleboard, multilayer board, hardwood |

| 16x105x165 | 16 | 16 | 105 | 165 | processing wooden door drilling, particleboard, multilayer board, hardwood |

| 16x18x105x165 | 16 | 18 | 105 | 165 | processing wooden door drilling, particleboard, multilayer board, hardwood |

Note: custom sizes available upon request to meet specific project needs.

Reduce Production Costs: Longer tool life means fewer replacements and lower overall tooling expenses..

Improve Efficiency: Faster chip removal and smooth cutting surfaces shorten machining time.

Ensure Product Quality: Burr-free and precise cuts enhance the quality of furniture, doors, and panels.

EVersatile Applications: One cutter fits multiple materials, reducing inventory and simplifying procurement.

Direct Manufacturer – Over 25 years of woodworking cutter production experience.

Improve Efficiency: Faster chip removal and smooth cutting surfaces shorten machining time.

Global Export Service – Supplying clients in Europe, America, and Asia.

Flexible MOQ – Supporting both bulk orders and small trial purchases.

Q1: What materials can this cutter process?

A1: It is suitable for wood, multilayer boards, particleboard, and hardwood.

Q2: Do you provide OEM services?

A2: Yes, we offer OEM/ODM solutions to meet your customization needs.

Q3: How do I choose the right diameter for my CNC machine?

A3: Please check your machine’s spindle capacity or contact our team for recommendations.

The Three-Flute Rough Milling Cutter combines precision, durability, and efficiency, making it the best choice for woodworking industry customers worldwide.

👉 Contact us today for pricing and samples – upgrade your CNC woodworking efficiency with our Three-Flute Rough Milling Cutter!